FAQ

See the current list on the Power Curves page.

In the PowerCurve Software, wheel speed and bike speed will be displayed. Wheel speed is the speed of the wheel based on the revolution times and the wheel circumference. It’s the speed the wheel is rotating on the trainer. For the same watts the wheel speed will vary based on the trainer because of the different power curves of each trainer.

The bike speed is a precise calculation of how fast you would be going outside based the current watts you are generating, the grade, your weight and aerodynamic factor profile calculated from your weight. Lighter riders are get a smaller frontal area than heavier riders. You’ll notice on downhills (negative grade settings) that without any pedaling, heavier riders will go slightly faster even though the have a larger frontal area.

But on an uphill, the same watts will make a lighter rider have a higher bike speed.

The magic of the PowerCurve Sensor and Software is that your bike speed will be accurate without being dependent on the trainer model since the bike speed is computed from the watts. And the watts will be accurate no matter which trainer you use!

Fluid trainers and wind trainers don’t have multiple resistance levels – the faster you pedal the more resistance is created by the trainer.

Most magnetic trainers have different resistance levels. With the PowerCurve Software, when you select the model of your magnetic trainer, it will be indicated which level to use. That means the power curve has been measured at that resistance level. Lower resistance levels means an easier resistance level.

The PowerCurve Software will often give you a choice of different resistance levels for the same trainer. Depending on how strong you are, choose a resistance level appropriate for you – so that you don’t spin out on hard intervals.

For an accurate power reading, it is important to not change the resistance level on your trainer once calibrated. To change the resistance change your gearing instead.

The primary difference between the PowerCurve Sensor and a torque based power meter (like a PowerTap, cranked based power meters) is that the PowerCurve Sensor determines the power for the speed to power relationship of a specific trainer.

There are a few considerations to be aware with the speed to power relationship (the “power curve”) of a trainer:

- The calibration precision

- The “drift” as heat builds up and dissipates

- The manufacturing differences between trainers of the same model

- Sudden acceleration and deceleration

The calibration is done using the coast down time of the trainer. There is a small tolerance for the coast down time, and trainers with a larger freewheel have a longer coast down time, so there will be less variability in the calibration. Another variability is the weight of your rear wheel compared to the wheel that was used to measure the power curve.

The “drift” as heat builds up can change the power curve itself. First, it is important before calibration to warmup the trainer and tire for 10-15 minutes. For wind trainers, resistance is created from the ambient air, so there should be very little heat drift. Magnetic trainers probably also don’t change their resistance too much with changes in temperature.

Fluid trainers could be affected by drift. First, the oil in the resistance unit will heat up and could make it less dense. Some manufacturers like Kinetic say that their oil is very “stable” and does not drift. This is probably true as the power curve measured for their fluid trainer was extremely close to their published power curve.

Fluid trainers tend to have “fins” to dissipate heat so the temperature should average out during the workout. So secondly, the type of workout, for example, steady state time trial or short sprints could also affect the oil temperature. Your average power too will also affect how much heat is generated.

Tire heat could also affect the resistance with the trainer roller. This stresses the importance again to warmup the tire and trainer before calibration. Different tire compounds will have different characteristics.

Trainers of the same model may have different physical characteristics. For example, who knows if a manufacturer has used the same oil in every production run? There might be slight changes in dimensions, magnet placement, bearings, etc…

Fast changes in speed will affect watts with a PowerCurve sensor. For example, if you do a 10 second sprint from a standing start, the power will be much lower on a PowerCurve. That is because the watts are determined from the speed, not the torque. On a 10 second standing start sprint, the maximum speed is not reached at maximum torque. It’s like having a lag, where the speed lags the torque. On the other hand, if you do an all out sprint from a rolling start at 30Km/H, the watts will be accurate because the maximum watts will occur very close to the maximum speed. During deceleration, the reverse happens, the watts will be higher and lag the speed. The average watts will remain accurate because for each acceleration, there will be a deceleration. What goes up must come down.

Even with all these considerations, during tests when comparing with a PowerTap, the discrepancy was usually very small, around 5-10 watts. In summary, don’t forget to warmup the trainer and tire. If the resistance unit generates heat, placing a small fan on the unit could keep things more consistent.

The PowerCurve Sensor is a USB HID device. In simpler terms, it means that it is similar to a USB keyboard or mouse. It takes its power from the USB port (no batteries required), and does not require any special drivers. It can’t get any simpler. Stationary trainers with different resistance units (magnetic, wind, or fluid) all have a different speed to power relationship. The key to precise measurement is:

- Repeatable results by measuring the press-on force between the wheel and the trainer. Differences in press-on force can account for discrepancies of 50 watts or more.

- A precise load curve.

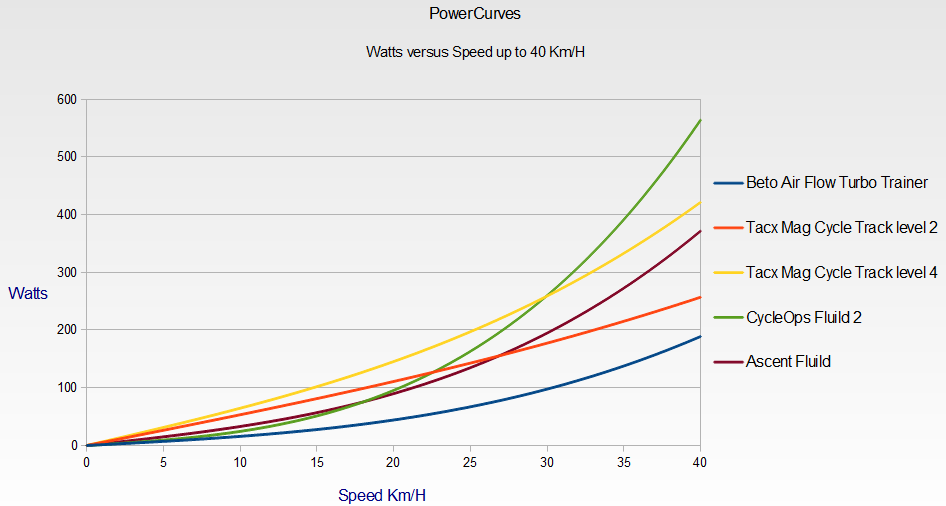

With a coast down test it is possible to measure the press on-force for repeatable results. Depending on the weight of the flywheel and the resistance of the trainer, different models will have different coast down calibration reference times. The trainers supported by the PowerCurve Sensor all have been calibrated with an appropriate coast down reference time. The load curves have been measured with a PowerTap at 8 or more different data points. Then with a mathematical third order polynomial curve fitting algorithm the precise load curve is established. Below is a graph showing a close up of the load curve for various trainers up to 40 Km/H.

Yes, PLEASE! We need speed values at 40, 80, 120, 160, 200, 240, 280,320,360 watts and the calibration coast time that was used. The coast time calibration is done with the PowerCurve software.

Contact us for more details.

The PowerCurve Software is a single EXE portable application. That means you just place it into a folder and run the program. Since it doesn’t store anything outside it’s folder you can even run it from an external disk or USB stick.

Do not install it in the “C:\Program Files” folder because on some Windows version the operating system will not allow creating files in the “Program Files” folder.

To keep things simple, you can create a folder in your C drive called C:\PowerCurve and extract the contents of the PowerCurve.Zip file that you downloaded to that folder. That’s it.

Yes, the PowerCurve Software will work using on a Mac if you are running Windows inside your Mac with with a virtualization software. It has been tested with VMWare Fusion. You first plug in the PowerCurve Sensor in a USB port. From the Settings icon, you select “USB and Bluetooth”, then you enable the PowerCurve Sensor so that it will be available to the PowerCurve Software.

It also works with the free Virtual Box virtualization software with USB support enabled.

Yes, you can connect more than one PowerCurve Sensor and have large groups all riding together. The PowerCurve Software will automatically detect when more than one sensor is plugged in.

Yes and no. In order to make a correlation between speed and watts, the bicycle trainer must increase the rotation speed as the pedal force increases. Common trainers in gym don’t behave that way. A PowerCurve Sensor can be used if you can attach the wheel sensor and magnet, but power will not be accurate as it is not possible to calibrate them. The wheel circumference value will need to be adjusted for realistic speeds depending on the design of the spin bike.